Our Products

Transformers manufactured by us confirm to national & international specifications IS : 2026, IEC 76 & BS : 171.We also design and manufacture transformers to meet customer’s need.

DESIGN

Technological excellence prevails at every stage of the manufacturing process. The design of transformers are developed based on the latest technology, using fully computerized design & drawings.

Each transformer design is done utilizing the latest software available – which helps in meeting national and international standards, to match customer’s requirement. Transformers are designed to withstand the rigourous conditions that may occur during service.

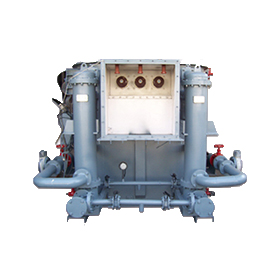

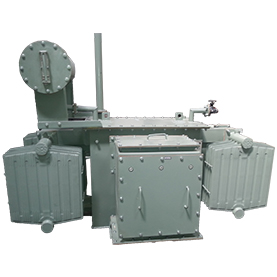

INDUSTRIAL APPLICATIONS

Wide range of Transformers up to 5000 KVA/33 KV class – having a vide scope in industrial use are manufactured by us.

MANUFACTURING PROCESS

Core Building

The Cold Rolld Grain Oriented (CRGO) lamination cut by microprocessors controlled slitting and cropping line with a very high dimentional accuracy are used to build core. Core laminations are assembled carefully and the built up core is erected along with the platform to avoid mechanical stress on the core Both legs and yokes and clamped by resin impregnated fiberglass taps instead of conventional yolce bolt to avoid local hot spots and bolt insulation failures.

Coil winding & Assembly

Spiral, Cross-over, Helical, Continuos Disc winding with multiple copper conductors are usually adopted for transformers. The coil are Lowred on the core legs. After top yoke filling is completed, the coil are precessed. Connection from winding to various terminal and bushing stap changers are made by paper insulated flexible conductors.

Drying

We take care for drying individual coil and insulation components to ensure that they match the duty cycle and short circuit forces, which the winding may encounter in service. The core and coil assembly is dried through a very efficient drying oven, which ensure extraction of moisture to zero level. After drying process, winding, clamping and connection are checked and tightened before lowering into tank. Filtered and degassed oil is then filled into the tank under vacuum and this oil is circulated through the vacuum filter plants until the required insulation level is achieved.

Final Assembly

During final assembly all pipe work, bushings and radiators are fitted to the transformer.

Products Range

TESTING

The testing laboratory is complete with the necessary equipments and high accurancy, precison instruments and testing facilities to conduct all the routine and Temperature rise type tests as per relevent standards for transformers.